摘要:Hoshin kanri in a picture 用一张图片来诠释方针管理 Words:

Hoshin kanri in a picture 用一张图片来诠释方针管理 Words: Nestor Gavilan, Director of Lean Learning, Instituto Lean Management – Barcelona 作者:Nestor Gavilan,巴塞罗那精益研究院主任

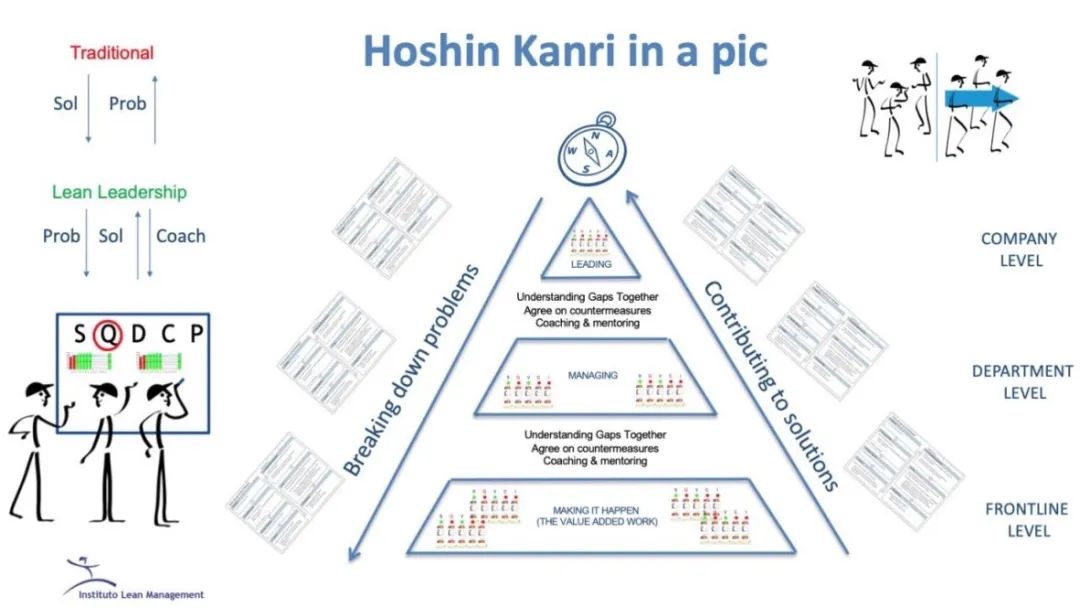

FEATURE – Hoshin is a powerful management practice that aligns the work at different levels to a company’s strategic goals. The author offers a one-page visual summary. 概要:方针管理是一套有效的管理方法,它将不同层级的工作与公司的战略目标联系起来。作者提供了一张图片的可视化总结。 In the average organization, front-line staff are often lost. Many times, they work without knowing what for and don’t feel engaged. Meanwhile, their managers are constantly called to fix problems on the floor to ensure the process runs and the leaders of organization – who are also in constant firefighting mode – find themselves having to fill in for the overwhelmed managers. Consequently, the front line is lost, trying to stay on top of the continuous changes in priorities. 许多公司里,一线工作人员经常会感到迷失,因为大多时候不知道自己为什么工作,也没有参与感。同时,他们的经理经常会被上司叫到现场去解决问题,以确保流程的正常运行。而更高层的领导们也处于救火模式中,去帮忙那些不堪重负的经理们处理业务。因此,一线员工往往迷失在追赶不断的变化中。 It’s like each layer of management is operating one level lower than they should. To work, however, a company needs its different levels to fulfill their proper roles: leaders should lead, managers should manage, and the front line should run the process. In order to create a proper balance, a company needs to find alignment on both its purpose and the actions that will make the purpose a reality. The most powerful tool for this is hoshin kanri, a practice that aligns activities and functions with strategic objectives. 管理层好像都在做着比他们职位低一级的工作;可是一个公司需要的是不同层级的员工履行不同的职责。比如领导层应该带领,经理层应该管理,一线员工则应该执行流程。为了达成适当的平衡,公司需要在目标和执行上达成一致;其最有效的一个工具就是方针管理(hoshin kanri,也有翻译成‘战略部署’),它将创造价值的工作和各职能部门的工作与公司战略目标串联起来。 A lot has been written about hoshin, including here on Planet Lean. The purpose of this short article is to summarize this concept in one graphic – something that you can go back to time and time again to see, at a glance, what strategy deployment is and how it works. 关于hoshin的文章多不胜收,包括Lean Planet网站上也曾登载过多篇。这篇文章的目的是用一幅图片来诠释这套管理方法;即使你一次又一次地回顾这幅图片,每次都可以领悟方针管理或战略部署的含义,并思考如何运作。

So, let me take you through it. 那么,让我为你解说。 One of lean’s biggest “innovations” is the idea that problems are cascaded from the top to the bottom of the organization and that it is up to the front line to come up with the best solutions – a far cry from the command-and-control attitude of traditional management, which is always expected to have the answer to any question. In a lean environment, leaders challenge people to come up with solutions, and through coaching and support they give them the tools they need to solve problems. 精益思想最大的一个“创新”就是它提倡一个假设:问题自上而下,交由一线人员来去想出最佳解决方案。这和传统管理的指挥和控制完全不同,因为传统体系的员工始终等待上级给出的解决方法。而在一个精益企业里,领导层鼓励员工去思考问题,并提出解决方案,通过辅导和支持给予员工需要的资源,一起去解决问题。 The A3 is typically the tool that makes this happen. To push a problem down to the front line means that the manager gives a team member the title and background of the A3 and asks her to work on its development to understand the current situation, analyze the problem and then “send up” a possible countermeasure. That’s where coaching comes into play, to help the team member reflect on the work done to understand the root cause, evaluate the countermeasures identified and take corrective action. Ideally, solutions travel from the bottom up thanks to the top-down coaching and mentoring provided. A3是一个典型的工具。经理将问题推给一线员工,定出A3要解决问题的题目和背景,要求他们研究和了解当前的状况,分析问题,然后提出对策,并且做试验获得结果,以求证对策的正确性。经理应发挥教练的作用,帮助团队成员反思工作中发掘出的问题、了解问题的根源,评估对策,采取纠正措施。理想情况下,自下而上的解决方案离不开自上而下的辅导和支持。 Indeed, the A3 is by far the most effective problem-solving practice we have in our lean arsenal, which is why both the process of breaking down problems and that of contributing solutions should use this powerful tool. (We see this represented in the graph with the A3s on both sides of pyramid.) In doing so, a company will develop a common language. So, a strategic A3 developed at leadership level (let’s call it “A3 1” or “mother A3”) will be use to analyze a problem and identify a number of countermeasures, which in turn will generate more A3s at department level (level-2 A3s or “sons A3s”, or A3 1.1, 1.2, 1.3, etc). Collectively, the A3s in the different departments spell out the contribution of each area to the achievement of the company’s strategic goals. The same thing happens at front-line level, where individual teams use A3s (A3 1.1.1, etc) to solve problems to get closer and closer to the expected department performance. 事实上,A3是迄今为止精益工具中最有效的问题解决方法,这就是为什么精益人在分析问题和解决方案的过程中都使用这个强有力的工具。(我们可以在金字塔两边的A3图中看到这一点。)如是,A3 可以被公司用来作为一个共同的解决问题语言。领导层的战略A3(或称之为“A3 1”或“母A3”)主要用于分析问题并定出若干对策。进一步将战略目标分解到部门层级,由部门拟定子A3 (或称之为2级A3或“子A3”或A3 1.1、1.2、1.3等);不同部门的A3里会明确相关部门对公司战略目标应承担的的部分。同样的,一线团队也有各自的A3(A3 1.1.1等)去解决问题。一旦每个团队都能完成A3 指标,则部门就越来越接近预期目标。 I have always seen A3s as a way to make hoshin more practical, more approachable. They force you to measure, get to know the current state intimately, and identify the root cause of a problem, thus providing a shared structure for the execution of a strategy. All too often leaders put the strategy on paper once a year, but then see it go nowhere because of a less-than-robust deployment process and a lack of monitoring of key indicators. It is rare to see A3 Thinking used consistently and a solid system in place for measuring impact and following up. It’s important, however, to ensure that the strategy is worked towards monthly, weekly, daily, and across all levels of the business. That’s why the graph has the image of the two men standing by a board carrying the SQDCP framework (Safety-Quality-Delivery-Cost-People) – it’s the best way to ensure we use indicators that give us a real sense of where we are and where we need to be. 我一直认为A3是一种让方针管理更实用、更容易落地的方法;并且引导团队深入评估和了解当前状态,并确定问题的根源,从而为执行策略提供一个共享框架。有些领导者一年一次地把战略写在A3纸上,但由于部署过程不够健全,而且缺乏对关键指标的日常监控,以致这些战略最终都无果而终。我们很少看到A3式思考方式被有效应用,并且缺乏一个管理体系来衡量结果,并后续跟进。无论怎样,重要的是要确保战略目标分解到月、周、甚至日指标,使得各层级都能跟进。这就是为什么图片上的两个精益小人站在一个写着SQDCP管理板旁边(Safety-Quality-Delivery-Cost-People 安全-质量-交付-成本-员工培育),这就是最好的目视化管理方式,以确保数据和指标可以真正地指出现状以及未来方向。

>>>>阅读更多《赵博士专栏》: 1. 【赵博士专栏】系列(第1-50篇) 13. 趙博士11月中国企业现场走线纪实(上) 14. 趙博士11月中国企业现场走线纪实(下) 15. LEC 2019回顾,2020 展望 16. 丰田再度挥舞精益魔杖 17. 无浪费的资本主义 18. 引入精益管理思维、创新自制防护用品 19. 中国企业新冠病毒后快速复苏的准备工作 20. 无浪费的资本主义(下) 21. 疫情期间一封来自日本专家的信-田中正知 22. 纽约市一周游 23. 美国新闻三冠王 24. 大疫之下,企业如何逆流直上? 25. 在疫情中维持情绪的平准化 |

- 上一篇:提质增效|合理化建议征集

- 下一篇:没有了

谈谈您对该文章的看